More information coming soon.

Home » Product Development Process » Complex Injection Molded Part Design

More information coming soon.

Individual part design is a foundational skill for product designers or design engineers. The best part designs are simultaneously driven by form and function. Manufacturing constraints, performance requirements and product life cycles are also woven into the process. 3D CAD modeling software is the primary tool used to develop parts

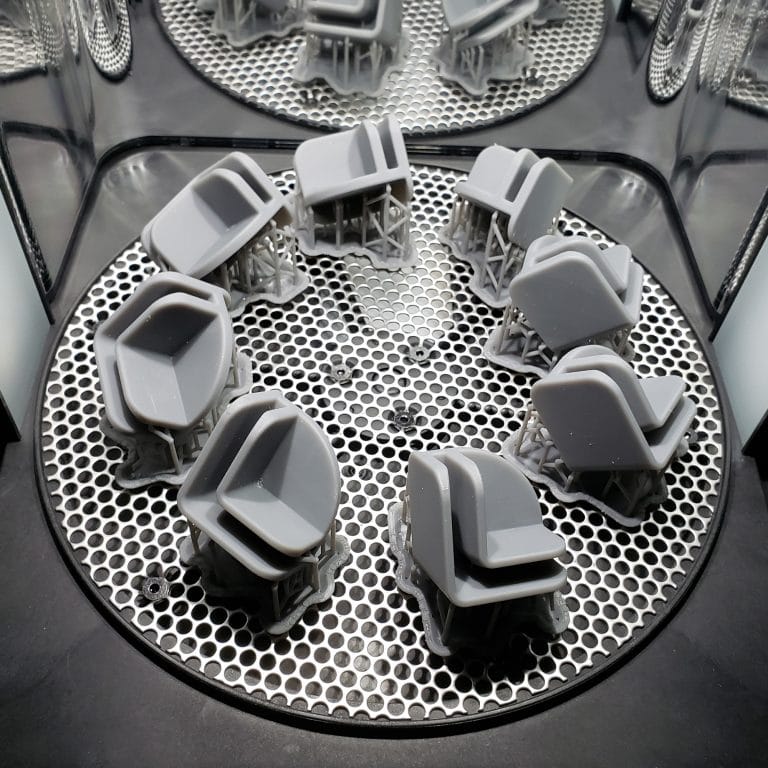

The ability to create quality prototypes is crucial to successful product development. Having prototyping capabilities in-house allow us to prove out concepts rapidly and cost effectively. We can take a concept, create a prototype, test it, tweak it, then build it again before before we would typically have received quotes

Manufacturing parts at quantities between prototyping and production.

It doesn’t matter how good a product is, if it can’t get manufactured it wont sell. If a client has a specific manufacturer in mind. We can design to their capabilities. Knowing this allows us to design strategically through out the development process. Ensuring that the product can be manufactured